Types of Robots

The most common type of industrial robot is a stationary robot—meaning robots that are bolted to a surface such as a floor, ceiling, or walls. There are five main types of stationary robots (or "robotic arms") currently in widespread use. They can accomplish tasks such as sorting, welding, and finishing. According to the International Federations of Robots, these five includes SCARA, articulated, cartesian, delta, and polar.

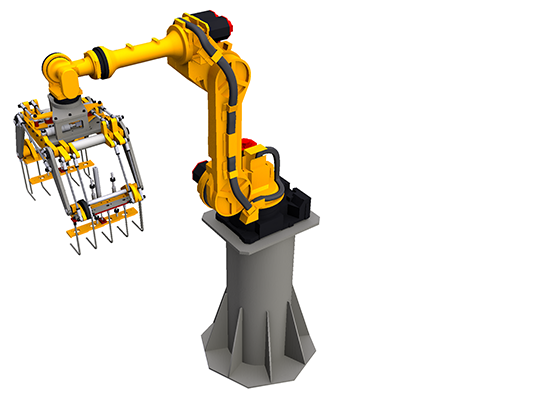

Articulated Robot

The most common industrial robot structure is the articulated arm, which accounts for 60% of installations worldwide, according to the International Federation of Robots. These robots resemble a human arm and have structures analogous to a shoulder, elbow, and wrist.

Articulated robots have between two to 10 joints which allows them a flexible range of motion to accomplish dynamic tasks. As the number of joints increases, the more “smooth” the robot’s motions become.

Typically, articulated arms can pivot six degrees of freedom. Although this is less than that of the human arm which can rotate seven degrees of freedom, the range of motion is sufficient for almost any task.

The robotic arm may be attached to a gripper, which is analogous to a hand. The gripper may be as simple as suction cups or as complex as hand-like structures with fingers that can grip and pick up objects.

Similar to robot type, the type of gripper is dependent on the task. Alternatively, grippers may be drill bits, sanders, lasers, and almost any type of specialized tool.

Because of their flexible range of motion allowed by joints, articulated robots have many applications. They are used most often for printing, packaging, welding, machine tending, material handling, and metalwork.

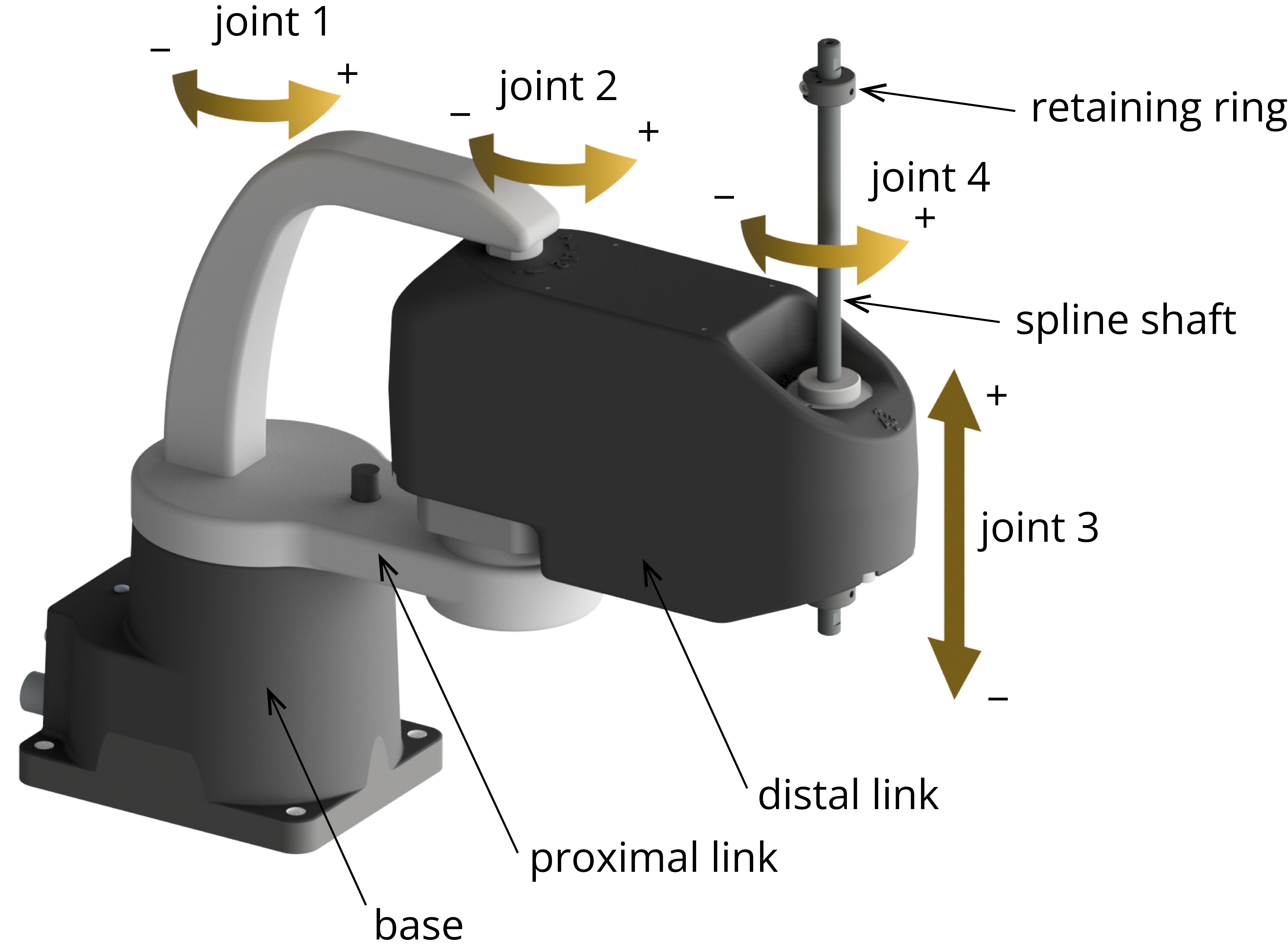

SCARA Robots

SCARA (Selective Compliance Articulated Robot Arm) describes robots with two parallel rotary joints. While SCARA robots are faster than Cartesian robots, they are less precise. Though they are able to move along all three axes, these robots specialize in lateral movements.

SCARA robots revolutionized small electronic manufacturing because of their small footprint, simplicity, and low cost. They are particularly well-suited for assembly applications. The "C" in SCARA stands for "compliance" and refers to the small amount of “give” in its horizontal plane. However, SCARA robots are rigid in their vertical plane, hence the naming structure of "selective compliance".

SCARA robot’s selective compliance is helpful for inserting parts into single-planes like circuit boards. Fitting a part into a hole requires some rigidity that is not possible with other types of robotic arms. However, SCARA robots have lower weight limits and fewer degrees of freedom due to this design.

Cartesian (Rectangular) Robots

Cartesian robots operate on three linear axes (forwards and backward, up and down, and side to side).

They get their namesake because they operate on the Cartesian Coordinate system (X,Y, and Z). In other words, they move horizontally and vertically in each ninety-degree plane.

Cartesian robots are frequently utilized for material handling, 3D printing, packaging, drilling, and storage or retrieval. Because Cartesian robots only operate linearly in three dimensions, their actions are more accurate. Additionally, they are more cost-effective and have simpler controls.

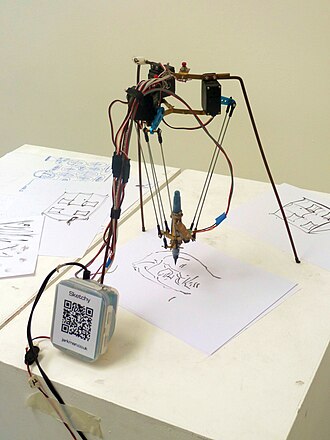

Delta Robots

Delta robots are popular in the manufacturing of food, pharmaceuticals, and electronics. Delta robots are frequently described as “spider-like” because they are crafted from jointed parallelograms connected to a base and are typically mounted above a workspace.

The Delta robot has sweet origins—it was originally created to pick up pieces of chocolate and place them in a box. Because of its light design, its motions are accurate and very fast.

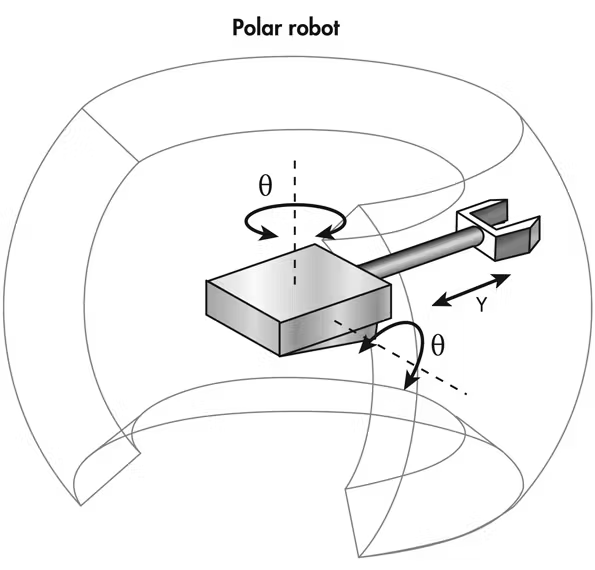

Polar (Spherical) Robots

Polar robots, also known as "spherical robots", possess an arm attached to two rotary joints and one linear joint. These robots move along polar coordinates, which allows a spherical range of motion.

The first industrial robot ever created was a spherical robot named "Unimate". Unimate worked on General Motors assembly lines beginning in the 1950s, transporting die castings and welding parts onto auto bodies.

While still in circulation, polar robots are considered slightly obsolete technology that can be replaced by more versatile articulated robot arms. However, polar robots can still be more cost-effective.

When deciding on which type of robot to select, it's most important to decide on the task or set of tasks it's required to perform. Additionally, prospective robot owners will need to think about interoperability with existing infrastructure. With a range of options on the market, manufacturers can weigh the costs and benefits to decide on the best model for their needs.

Related Information

This text was adapted with permission from 5 Types of Industrial Robots. NRTC Automation.

Delta robot. Wikipedia

Polar (spherical) robot. Machine Design

Information and programs provided by admin@mcmassociates.io.